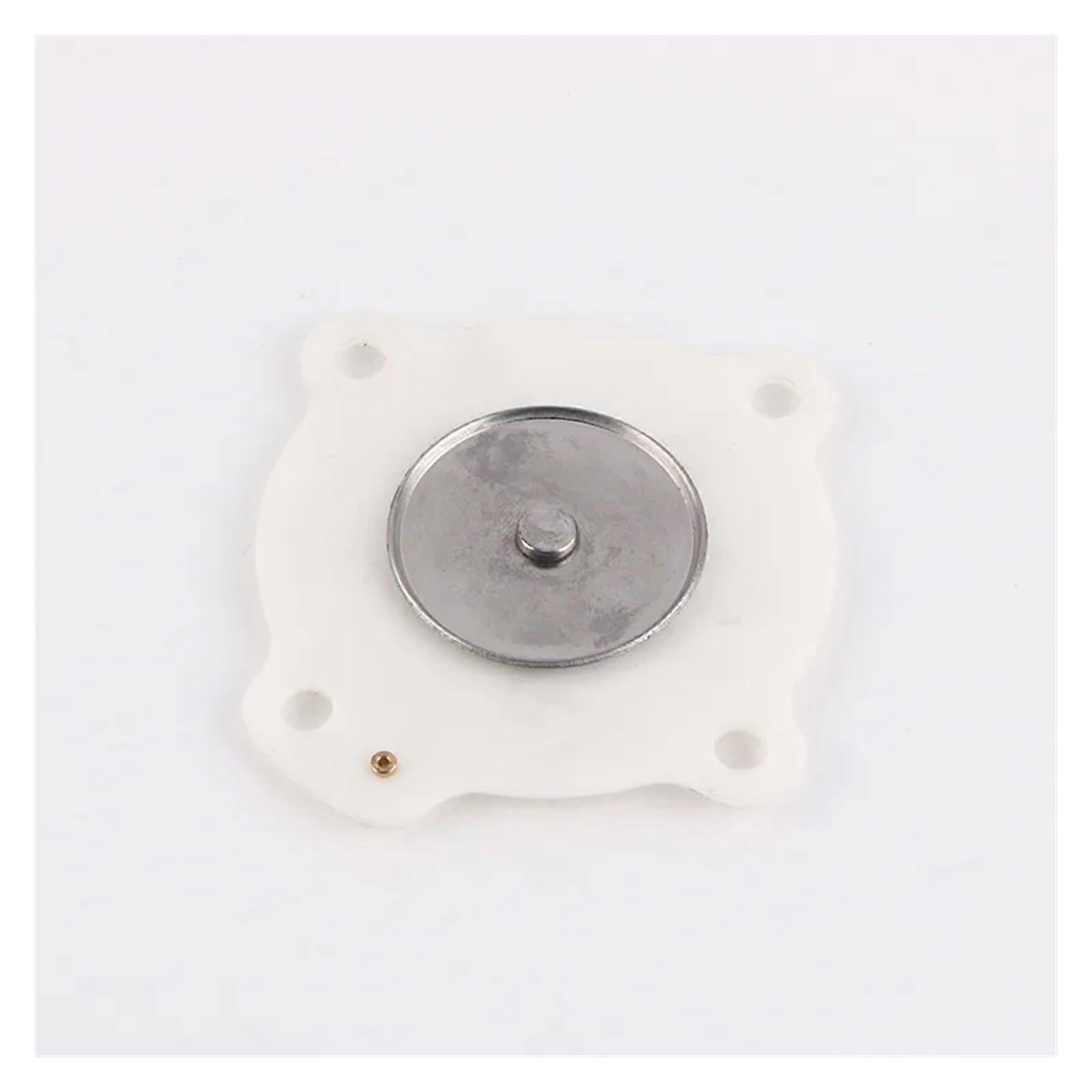

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

gratis leverans

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Märke: Unbranded

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Märke: Unbranded

| Rekommenderat återförsäljningspris: | |

| Pris: | |

| Du sparar: | 14,00 US$ (32%) |

Moms beräknas i kassan

I lager

14-dagars returpolicy

Vi erbjuder följande betalsätt

Beskrivning

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Märke: Unbranded

- Kategori: Rörventiler

- Fruugo-ID: 375907553-813574527

Produktsäkerhetsinformation

Se produktsäkerhetsinformationen som är specifik för denna produkt som beskrivs nedan

Följande information tillhandahålls av den oberoende tredjepartsåterförsäljaren som säljer denna produkt.

Leverans och returer

Skickas inom 24 timmar

-

STANDARD: GRATIS - Leverans mellan kl mån 29 december 2025–ons 14 januari 2026 - GRATIS

Leverans från Kina.

Vi gör vårt bästa för att säkerställa att produkterna du beställer levereras kompletta och enligt dina specifikationer. Om du däremot skulle ta emot en ofullständig beställning, eller andra artiklar än de du beställt, eller om det finns någon annan anledning till att du inte är nöjd med din beställning, kan du returnera beställningen, eller valfria produkter som ingår i beställningen, och få fullständig ersättning för artiklarna. Visa fullständig returpolicy

Produktöverensstämmelsedetaljer

Vänligen se överensstämmelseinformationen som är specifik för denna produkt som beskrivs nedan.

Följande information tillhandahålls av den oberoende tredjepartsåterförsäljaren som säljer denna produkt.

Tillverkare:

Följande information beskriver kontaktuppgifter för tillverkaren av denna produkt som säljs på Fruugo.

- DelightDew

- Shenzhen Tumi Technology Co., Ltd.

- 202-03, Jinhe Building, 8 Xinhe Street, Maan Tang, Bantian

- Longgang, Shenzhen, Guangdong

- China

- Shenzhen

- CN

- 518129

- pettynfnef@outlook.com

- 13332965772

Ansvarig person i EU:

Följande information innehåller kontaktuppgifter för den ansvariga personen i EU. Den ansvariga personen är den utsedda ekonomiska aktör i EU som ansvarar för att skyldigheterna uppfylls för denna produkt som säljs till Europeiska unionen.

- Synertrade FR SAS

- Synertrade FR SAS

- 9 rue du Bat d'Argent

- Lyon

- France

- Lyon

- FR

- 69001

- info@syner-sarl.cn

- (+33)774555006

- https://seller.kuajingmaihuo.com/settle/qualification-service