描述

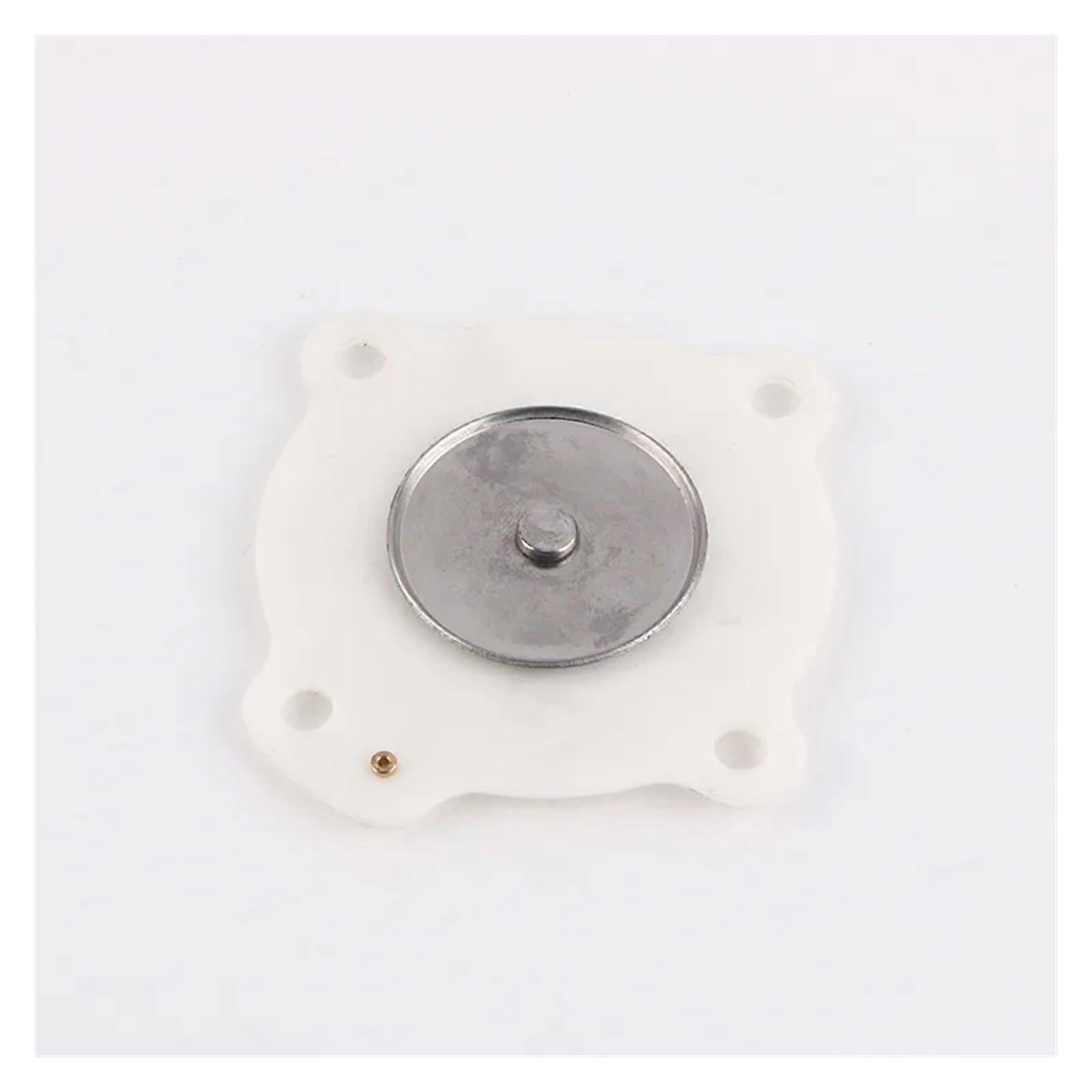

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

Control Valves

Overview

A control valve modulates flow in a piping system to maintain a setpoint for process variables such as flow, pressure, or temperature. It uses an actuator to move the valve mechanism (seat, plug, or disc) in response to a control signal. The result is precise, stable process control with reliable shut-off when the valve is fully closed.

Key benefits

- Precise modulation: ensures target flow or pressure is reached with minimal overshoot and short response time.

- Reliable shut-off: tight sealing reduces leakage when closed, supporting system integrity and safety.

- Broad media compatibility: suitable for water, oil, gas, steam, and many chemicals when paired with appropriate materials and seals.

- Durable construction: available in common industrial materials such as stainless steel, carbon steel, bronze, and ductile iron to fit demanding service conditions.

- Flexible actuation: supports electric, pneumatic, or hydraulic actuation, with compatibility to standard control systems and optional positioners or feedback devices for closed-loop control.

- Easy installation and maintenance: modular design, standard end connections, straightforward disassembly for service, and predictable maintenance intervals.

- Consistent performance: designed for stable control with reliable endurance under typical process fluctuations and cycle demands.

Attributes to consider

- Function: modulates fluid flow to maintain setpoints for process variables; provides controlled opening and closing for precise regulation.

- Compatibility: suitable for a range of media when equipped with appropriate seals and materials; compatible with common control signals and mounting styles.

- Size: offered in multiple pipe sizes to fit upstream and downstream components; selection aligned with valve Cv/Kv requirements and system needs.

- Material: construction options include stainless steel, carbon steel, bronze, and ductile iron; seats and seals available in EPDM, Viton, PTFE, and other materials to suit media and temperature requirements.

- Performance: emphasis on accurate positioning, tight shut-off, low hysteresis, and long valve life; designed to meet applicable industry standards for safety and reliability.

- Actuation options: electric actuators, pneumatic actuators, or hydraulic actuators; compatibility with local control systems; optional feedback and position indication.

- End connections: diverse connection types such as flange, tri-clamp, butt weld, or threaded ends to fit existing piping layouts.

- Standards and certification: designed to conform to relevant industry standards and operating conditions; available configurations may include certified options as required by the application.

Use scenarios

- Chemical processing dosing loop: deployed to regulate the flow of a reactant into a mixer, maintaining precise concentration and reaction conditions with rapid response to control signals.

- HVAC plant primary and secondary loops: used to modulate chilled or hot water flow in response to temperature setpoints, improving energy efficiency and comfort while protecting equipment from thermal shock.

- Water treatment and distribution: employed for precise dosing of coagulants or disinfectants and for balancing flow in distribution networks, supporting consistent water quality and system pressure.

Installation and operation tips

- Select the valve size and Cv/Kv to match the system’s flow demand and pressure characteristics for accurate control.

- Choose materials and seals that suit the media, temperature, and potential chemical exposure to minimize wear and leakage.

- Pair the valve with an appropriate actuator and, where needed, a positioner or feedback device to achieve reliable closed-loop control.

- Ensure proper alignment and mounting orientation to optimize actuator performance and longevity.

- Implement routine inspection and maintenance of seals, seats, and actuators according to service conditions and manufacturer recommendations.

This description provides a concise, practical overview of control valves with emphasis on function, compatibility, size, material, and performance. It includes 2-3 concrete use scenarios to illustrate practical application, and it maintains a professional, trustworthy tone suitable for informed purchasing decisions.

-

Fruugo ID:

375907553-813574527